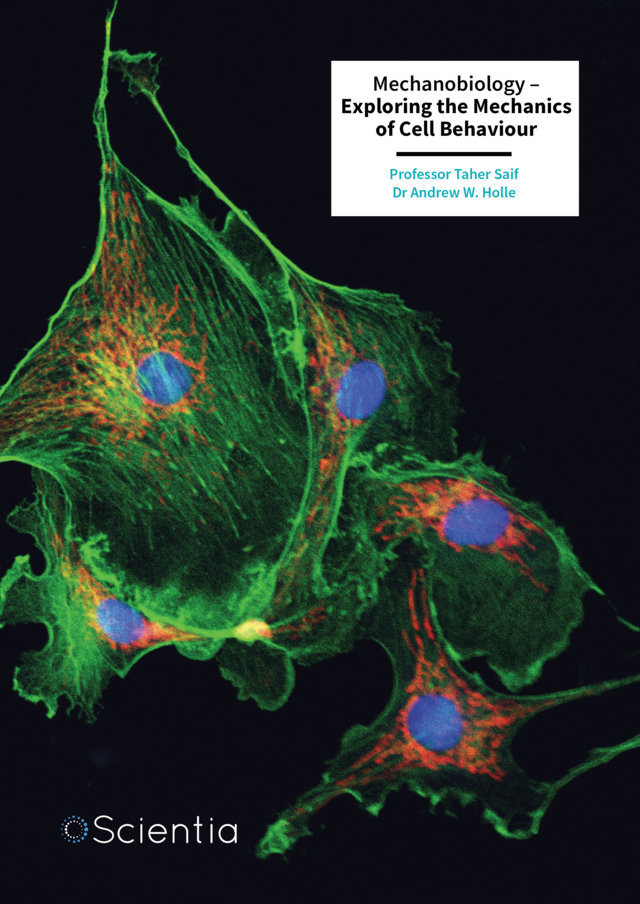

A future where injured or diseased organs can be removed and replaced with new lab-printed tissues that are customized specifically for each patient is not as far away as you might think. These functional and living tissues could grow naturally within the body, and repair and sustain themselves over time. While these concepts were once in the realm of science fiction, advances in bioprinting, which is a form of 3D printing using biological “inks” (known as bioinks) loaded with living cells, are bringing them closer to reality. Among the researchers advancing this field is Dr. Mingjun Xie of Zhejiang University, China, and colleagues, who are performing work that addresses a significant challenge in bioprinting. This involves creating large portions of tissues that have a functional vasculature, thereby mimicking the complexity of native tissues and organs. More

Bioprinting typically involves layer-by-layer 3D printing using bioinks made from biomaterials such as gelatin, which are often combined with living cells. This technology has already successfully produced simple tissues such as cartilage, skin, and even miniature organoids, which are tiny versions of organs used for research. However, printing larger, organ-scale tissues has long been a stumbling block.

The problem lies in a process called vascularization, which is the formation of blood vessels within a tissue. In our bodies, blood vessels deliver oxygen and nutrients to cells and remove waste products, much like the plumbing system in a house. Without these “pipes,” cells in the interior of thick tissues cannot survive. Attempts to manually design and print vascular networks have shown promise, but these methods are time-consuming, costly, and prone to errors, especially for larger tissues.

Dr. Xie and colleagues have developed an innovative bioink designed to overcome these limitations. The key lies in the use of microspheres, which are tiny, temperature-sensitive beads. These microspheres are made from gelatin, a material derived from collagen, which forms the connective tissue in our bodies. The researchers seed the biospheres with human umbilical vein endothelial cells (HUVECs), the type of cells that naturally form blood vessels in the body.

The goal is to incorporate these HUVEC-seeded biospheres into a larger bioink matrix, where the microspheres can act as temporary scaffolds. The bioink also contains a material called gelatin methacryloyl, which forms a crosslinked structural framework when exposed to light, helping to enhance the strength and durability of the printed tissue.

Here’s where the magic happens: once the tissue is printed and exposed to body temperature, the gelatin microspheres dissolve, leaving behind a network of tiny pores. These pores act as pathways for nutrients and oxygen to flow through the tissue, much like blood vessels, keeping the cells alive. The endothelial cells released from the dissolved microspheres settle along the edges of these pores and begin forming blood vessels.

To test their bioink, the researchers printed a centimeter-scale model of breast tumor tissue. This size is significant because traditional bioprinting methods often fail to keep cells alive in structures larger than a few millimeters. The printed tissue was loaded with two types of cells: tumor cells and endothelial cells.

The results were remarkable. Over the course of a few days, the endothelial cells began forming networks of blood vessel-like structures. By the end of the experiment, these networks had grown and branched, mimicking natural blood vessel formation processes. The tumor cells, nourished by the vascular channels, thrived and proliferated, creating a realistic tumor model.

Notably, the researchers observed that the vascularization process could be controlled by adjusting the size and number of the gelatin microspheres. Smaller microspheres created more evenly distributed pores, while larger ones formed larger channels. This flexibility allows researchers to tailor the bioink for different applications.

This bioink successfully addresses two critical challenges in bioprinting. The first is nutrient delivery. The porous networks left by the dissolving microspheres ensured that every cell in the tissue had access to oxygen and nutrients, solving the problem of cell suffocation in large structures.

The printed constructs also addressed another significant challenge in bioprinting, by enabling vascularization in the printed constructs. By incorporating endothelial cells directly into the printing process, the bioink enabled the natural formation of blood vessels, reducing the need for complex post-printing interventions. This innovation not only improves the survival of printed tissues but also brings us closer to replicating the complexity of living organs.

The potential applications for this bioink are vast. While the researchers focused on creating a breast tumor model to study cancer progression and drug testing, the same approach could be used to create functional tissues for other purposes.

For instance, doctors could use the bioink to print tissues to repair damaged organs, such as regenerative patches for heart tissue after a heart attack or liver tissue for patients with cirrhosis. Pharmaceutical companies could use vascularized tissue models to test drugs more accurately, reducing reliance on animal testing and speeding up the drug development process.

Researchers could also study conditions such as diabetes or cardiovascular diseases in realistic tissue models, gaining insights into disease mechanisms and testing potential therapies. With sufficient development, such systems may even provide lab-created options for full organ transplantations.

Dr. Xie and his colleagues have provided a powerful tool that could transform medicine. Their bioink enables the creation of living, vascularized tissues at a scale and complexity previously unattainable. While challenges remain, such as scaling up production and integrating bioprinted tissues into living organisms, Dr. Xie’s work demonstrates that these obstacles can be overcome with ingenuity and collaboration.

These advances remind us of the power of science to tackle complex problems. By combining biology, materials science, and engineering, these researchers have opened the door to a future where personalized medicine is the norm, and the limits of human health and healing are redefined. With every new innovation, the dream of repairing or replacing damaged organs grows closer.